Solution concepts for the integration of high-power batteries in high-performance small series: concept and design competence for AM structural components in complex environments

High-performance battery boxes with lithium-ion capacitor modules instead of lithium-ion battery modules make higher charging and discharging currents possible, while protecting the main battery. Due to the resulting higher temperatures, however, these require cooling over and above that provided by conventional cooling systems.

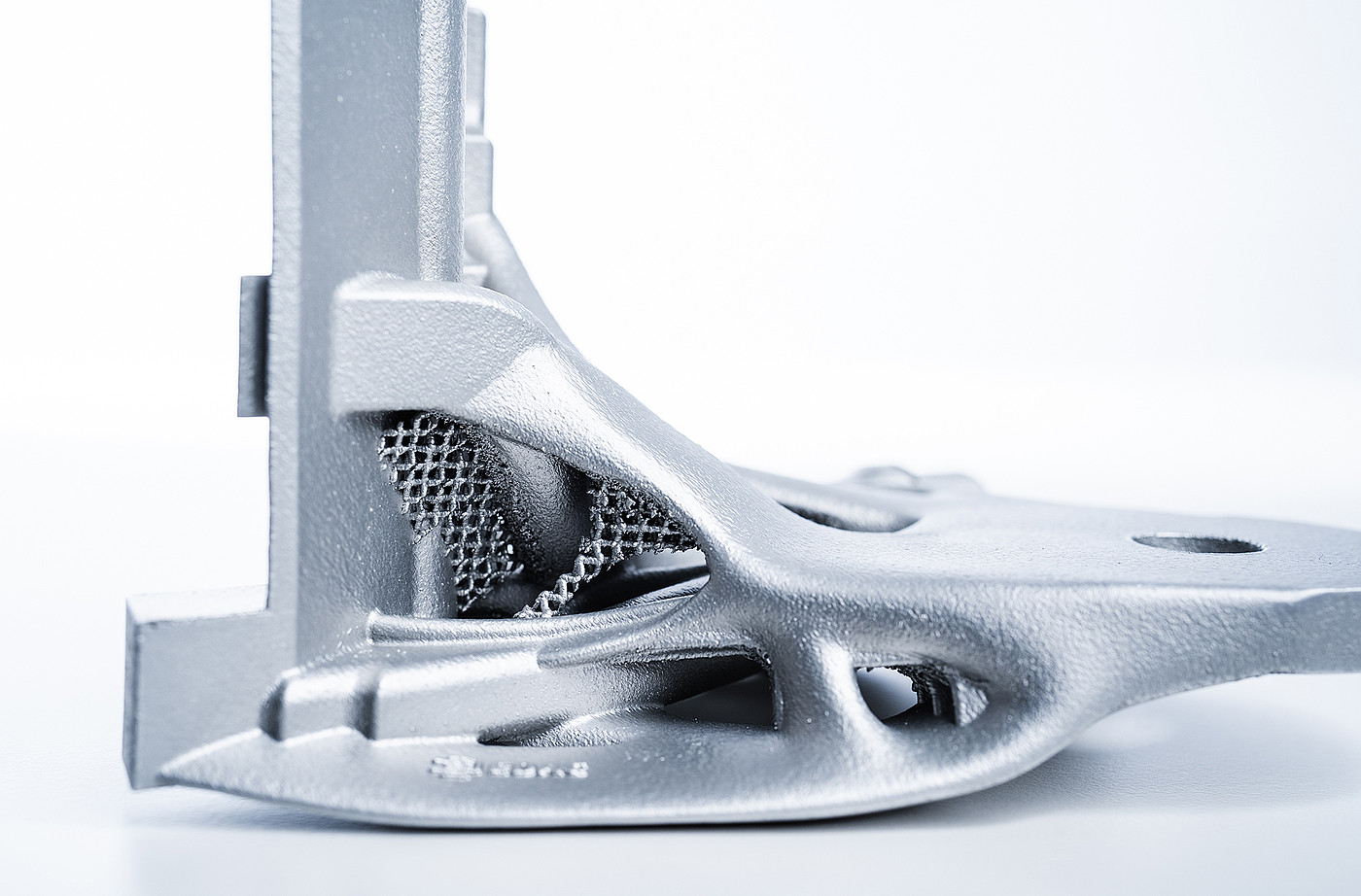

Unlike conventional battery boxes, the technology carrier developed for the integration of a modular auxiliary battery consists of extruded aluminium sections and additively manufactured nodes. The structure of the Scalmalloy® (high-strength aluminium alloy) AM nodes was designed for a crash load case by means of topology optimisation, and the functions for media distribution, section connection, reinforcement and connection were also integrated. The rear node in particular plays an important role here, as this is where the central media distribution system is integrated.

In addition, design concepts for the operationally stable design of additively manufactured components made of Scalmalloy® and Inconel 718 were developed in the project, and are available for future development tasks.

The model is set up parametrically, and can be adapted to individual customers' specific applications. Compared to a conventionally produced version using aluminium die-casting, the concept can be economically implemented for up to 3,400 components p.a. With high-end vehicles or derivatives in low-volume series in particular, the added functional value can be significantly increased through individualisation and function integration.

The work was sponsored by the German Federal Ministry of Education and Research (BMBF) under the project number 02P15B155, and by the Project Management Agency Karlsruhe (PTKA). Our partners in this collaboration were, under the direction of Fraunhofer LBF, Airbus Group Innovations, Heraeus, Sogeti High-Tech, the Technical University of Darmstadt (MPA-IfW and PTW), Linde AG, Robert Bosch GmbH, EOS GmbH und C.F.K. CNC-Fertigungstechnik Kriftel GmbH.

Do you want to make your products and development methods fit for the production technologies of the future? With their experience in topology optimisation, function integration; production-oriented design and operationally stable design, Richard Kordaß will be happy to offer support.

Similar projects:

VariKa: Efficient development and production of multi-variant vehicle body modules thanks to networked product and production engineering

ScaleBase: Scalable floor assembly for electric vehicles

OptiAMix: Additively manufactured rear wing system facilitates active aerodynamics

CustoMat3D: Aluminium alloy CustAlloy® for higher strength and greater elongation at fracture