Use of natural fibre-reinforced bio-based plastic composites as sustainable materials for a safety-relevant structural component

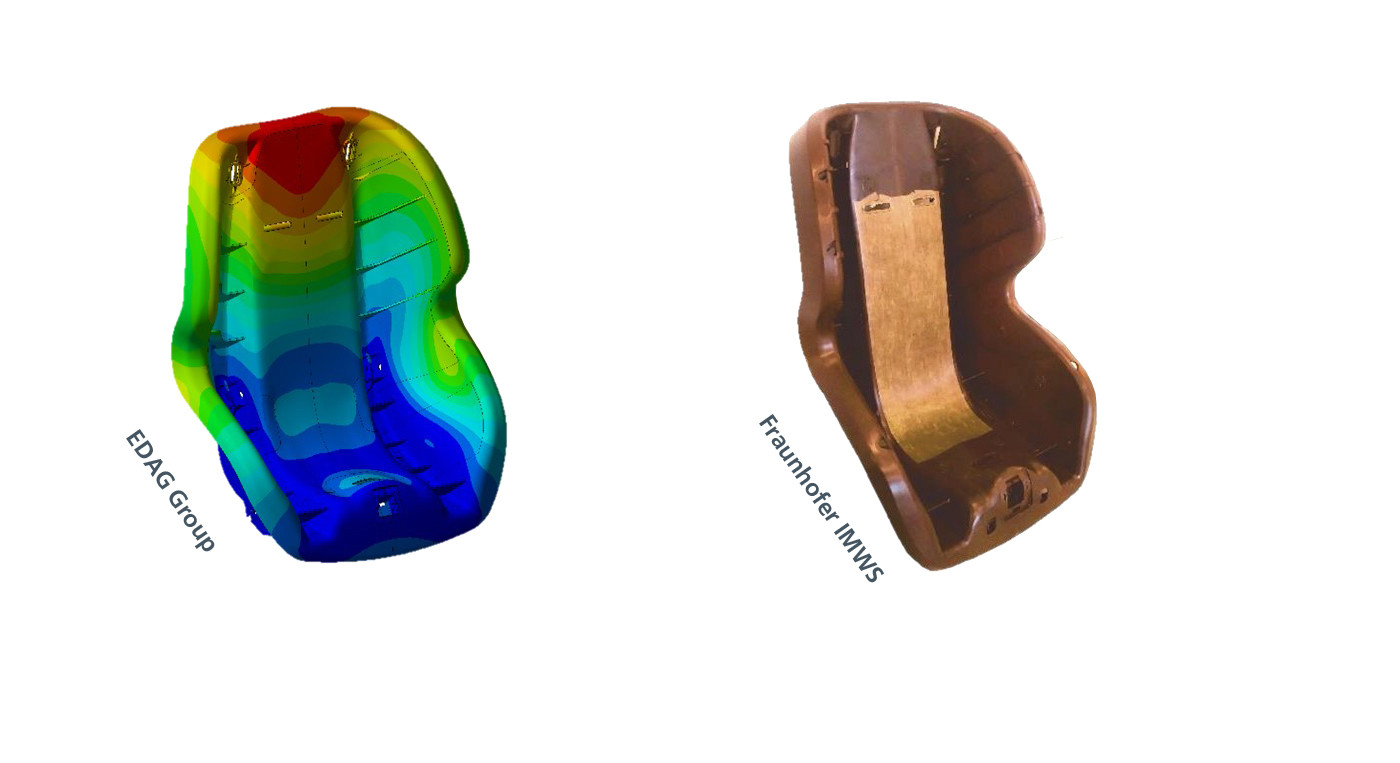

In the future, high-stress structural components in automobile applications are also to be produced using sustainable resources. With this in mind, in the composite research project "RegScha", we researched the potential of biopolymer-based natural fibre-reinforced plastics (bio-NFRP) in terms of structural, crash and safety relevance, developed a seat shell for a child car seat in composite design which meets the high structure and safety requirements in force, and simulated its crash performance. It also exhibits a weight reduction compared to the reference structures.

In the next few months, its performance in physical crash tests is to be examined by associate partner Britax Römer, a series manufacturer of child car seats.

Our research partners also developed a process and performance additive for bio-NFRP injection moulded materials and an NFRP semi-finished product for the production of bio-tape using innovative coating systems. In addition, processing principles were worked out, the materials mechanically characterised, and a production process for bio-NFRP semi-finished products and bio-NFRP hybrid moulded parts developed.

Our project partners are Evonik Perations GmbH, SachsenLeinen GmbH, the Technical University of Chemnitz, and Fraunhofer IMWS. Associated project partners are Britax Römer, GK Concept GmbH and KNOTEN WEIMAR Internationale Transferstelle Umwelttechnologien GmbH.

This project was sponsored by the Federal Ministry of Food and Agriculture (BMEL) via the Agency for Renewable Resources(FNR) under a resolution passed by the German parliament.

Would you also like to switch your focus to automobile applications that are sustainable but safe? We will be happy to support you. Michael Begert looks forward to hearing from you.