At the IAA in Frankfurt, the EDAG Group will be presenting not just its live engineering project #collectivio, but also seven technological innovations from the fields of lightweight design and eMobility. As the growing number of variants continues to increase due to the alternative powertrains available, greater flexibility and above all more lightweight solutions, both for components but also in manufacturing, are called for. Wiesbaden-based engineering specialists EDAG have already in recent years provided impressive evidence of the company's engineering skills in additive manufacturing. EDAG are continuing this success story this year with two innovative lightweight materials, in cooperation with 3M.

For us, lightweight design competence, car IT and production solutions remain key future oriented subjects. I am delighted that we can once again offer a real firework display of proactively developed technology concepts in these future fields here in Frankfurt," declares Jürgen Vogt, CEO of the EDAG Group.

3M Glass Bubbles - a versatile lightweight filler

EDAG and 3M, the multitechnology company, will be joining forces at the IAA, and presenting a new ingredient for an innovative recipe for lightweight design: 3M Glass Bubbles. Key characteristics: spherical and hollow with a glass shell. And more than anything else: lightweight. Lightweight and also easy to handle. With a density of just 0.46 g/cm³, and depending on filling degree and formulation, it is possible to reduce the weight of plastic systems by up to 30 percent with 3M Glass Bubbles iM16K. 3M glass microspheres are ideal for applications that serve the megatrend lightweight design, and can already be found in every fifth car.

Further advantages of this new type of filling material in composite materials are its good thermal insulation and quick cooling properties. The Glass Bubble iM16K has been successfully incorporated into a polypropylene matrix. In a joint study, EDAG was able to identify applications in the vehicle interior, exterior and engine compartment, in which the use of Glass Bubbles also proved successful in thermoplastic materials. In injection moulding tests, it was shown that this material substitution had a positive effect on the manufacturing process, cycle time and therefore also on costeffectiveness. The first series applications involving the Glass Bubble iM16K are already close to implementation. At the IAA, EDAG and 3M will be presenting a door trim featuring a lightweight Glass Bubble compound. This highlights the fact that the new filler makes plastic compounds lighter, while at the same time also meeting vehicle manufacturers' and suppliers' technical requirements.

New lightweight damping material

The science behind silence - every gram counts.

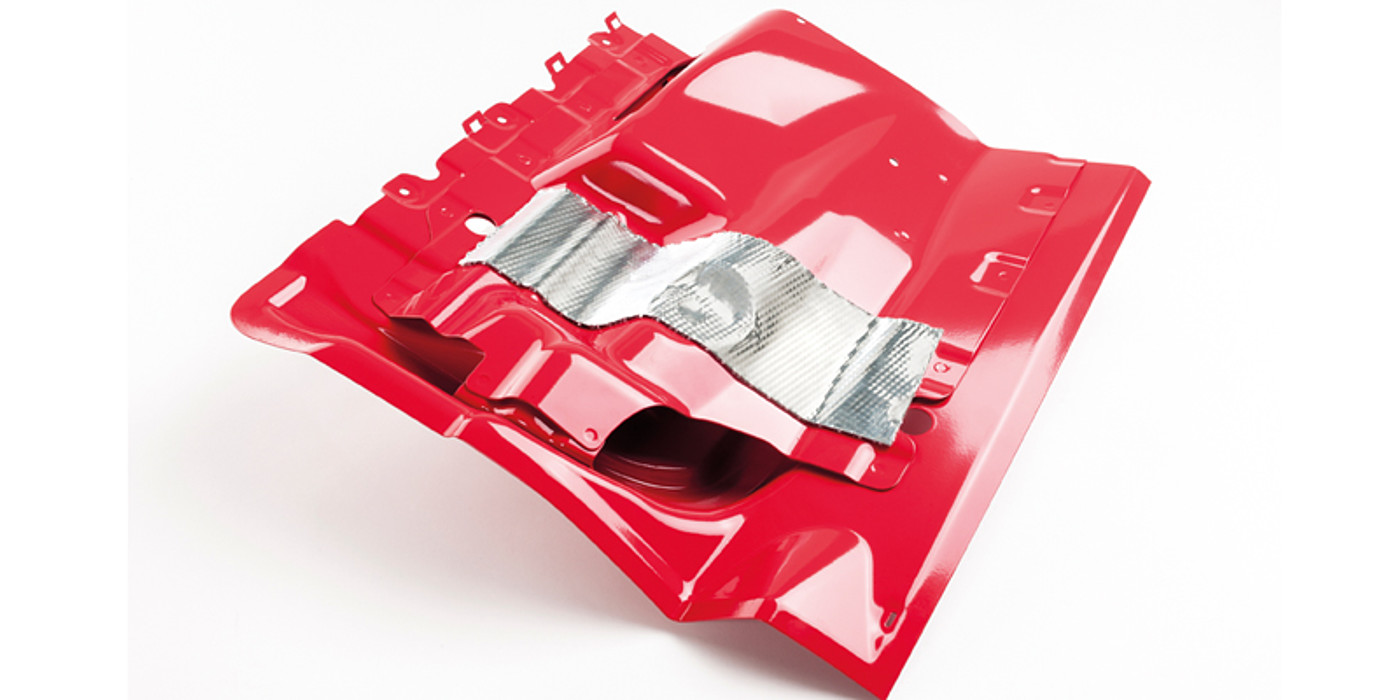

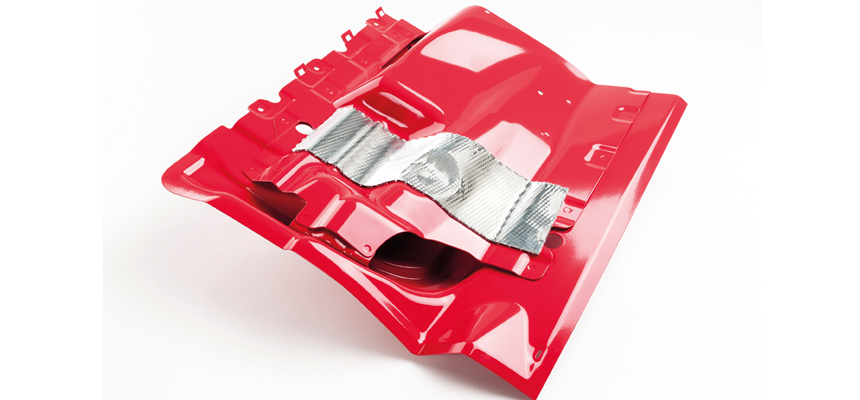

EDAG and 3M will also be joining forces at the IAA with a presentation of a new damping technology developed by 3M, to demonstrate their cooperation in the field of acoustic engineering. 3M's new lightweight damping material was developed to reduce structureborne noise in lightweight design applications for vehicles. Engineering specialists EDAG carried out a study to identify and evaluate interesting target applications aimed at weight reduction and goaloriented function integration for the following fields of application: automobile, eMobility and commercial vehicles.

The initial results show that, compared to other "constrained layer" damping solutions, significant weight reductions can be achieved while maintaining the same damping levels.

The study revealed that the stiffening effect of the damping material in the composite material can contribute, for instance, to an improvement in dent resistance when used in the vehicle body. The material is suitable for automatic application in the assembly process, which contributes to a reduction of the cycle time and to an improvement in the positioning accuracy, and might therefore also lead to cost savings. To this end, EDAG developed a robotassisted gripper concept which can be integrated in the vehicle assembly process. The product launch is planned for 2018.

About 3M

3M, the multitechnology company, was founded in Minnesota, USA, in 1902, and is today considered to be one of the world's most innovative companies. With a workforce of more than 90,000, 3M is represented in 200 countries, and in 2016 generated sales revenues in excess of 30 billion US dollars. The company's innovative strength is based on the diversified use it makes of the 46 technology platforms it owns. Its portfolio today includes over 50,000 different products for just about every area of life. 3M holds more than 25,000 patents, and about a third of its sales revenue comes from products that have been on the market for less than five years. For further information see: www.3M.en, Twitter and Facebook.