Architects, theatre experts and film directors know all about the lighting effects, and make careful use of lighting moods to create a particular emotion or atmosphere. The automotive industry, too, has discovered and begun to make use of light as a powerful and effective design element. Light has long since ceased to be simply a necessary feature for lighting up the road – light is now used "on" and "in" the car to create distinctive impressions. One example of this is the idea Audi had some years ago of equipping its fleet with LED daytime running light, which has helped to establish a highly visible recognition feature.

Reason enough for EDAG to add to its skills in the vehicle development process the subject of light, with all its many facets - from the transfer of styling language into in technical surfaces, through the design and simulation of photometric surfaces to electrical controls in the interior and exterior.

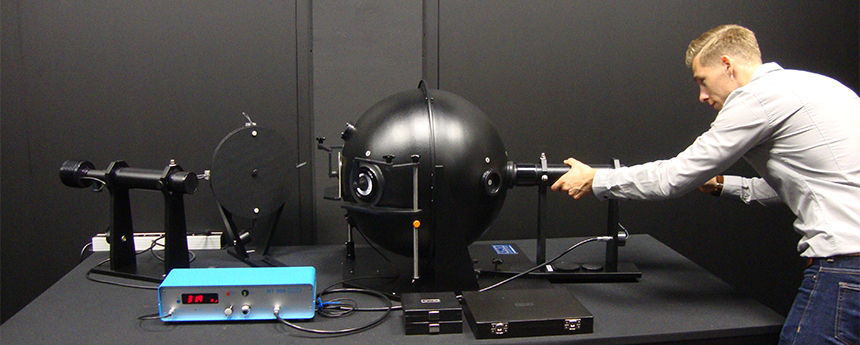

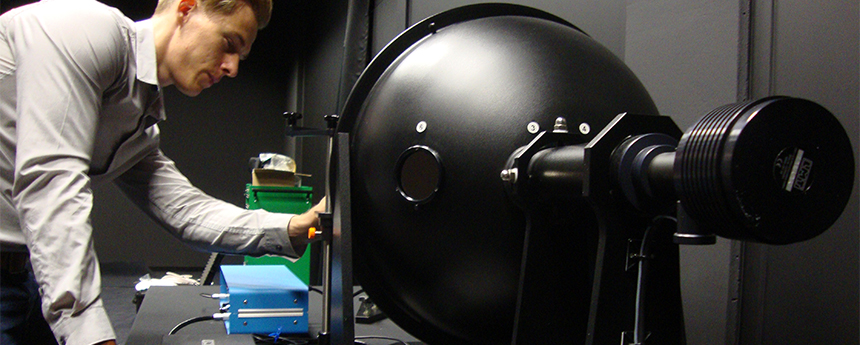

In April 2016, the Lighting Technology and Simulation team, moved into EDAG's new light laboratory at the Wolfsburg site, along with the Light + Sight team. "We now have better conditions and more space than we had at the old site in Schweriner Straße to map light technology components, not just virtually and in prototype construction, but also then to test their operability in trials", underline Franziska Lange, Martin Fiege and Philip Schatz. "To this end, the brightness and light colour of samples can be examined in the new laboratory."

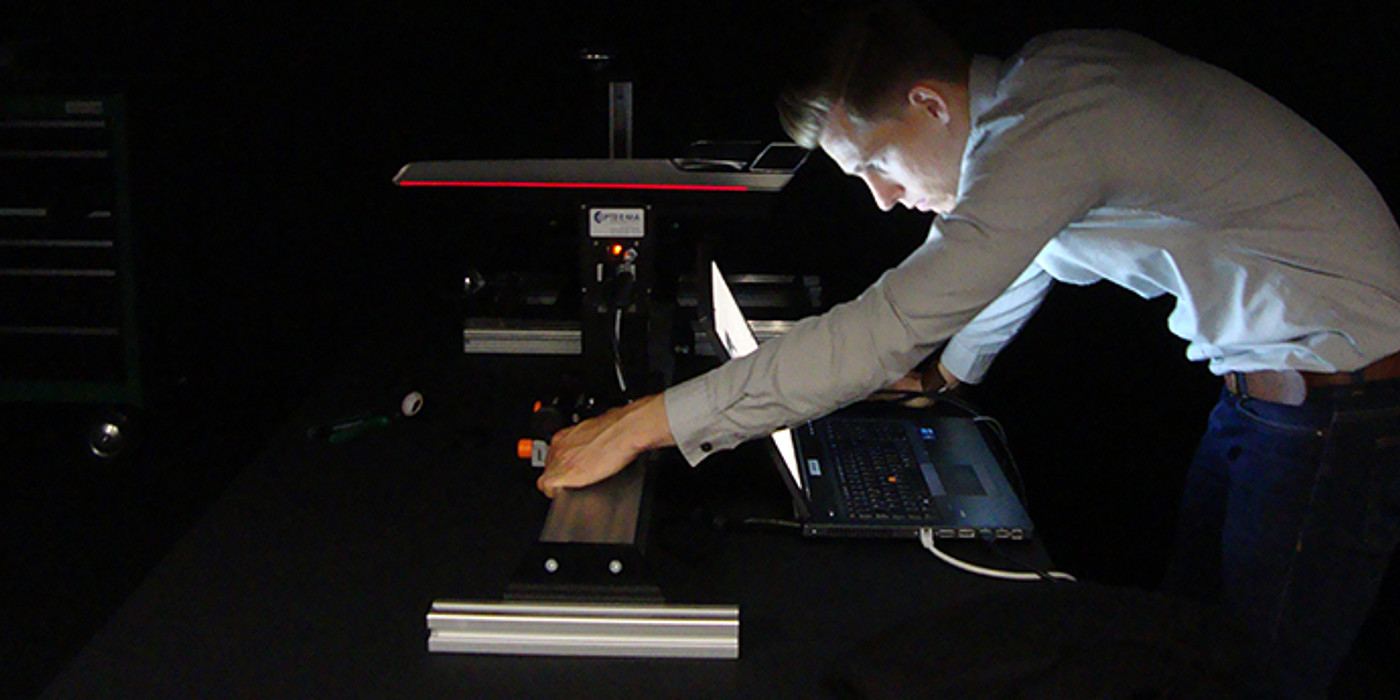

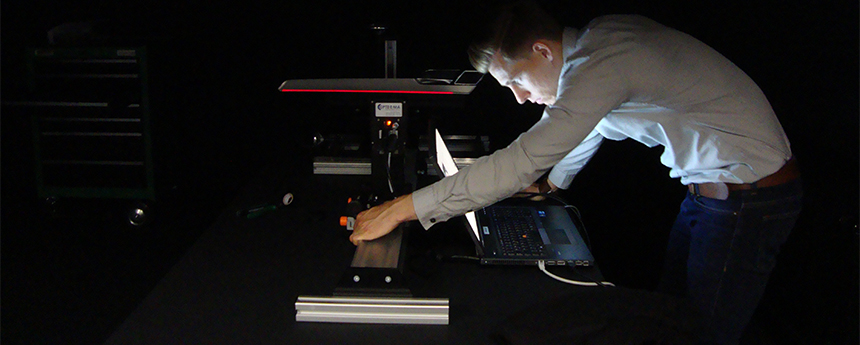

One apparent paradox is that when you enter it, the light laboratory is in pitch darkness. The room is painted matt black all round to ensure the non-reflective surfaces essential for obtaining comparable measured values. Constant climate control keeps the laboratory at a temperature of 20 degrees Celsius, thus providing ideal measuring conditions.

Working in a laboratory measuring more than 60 m² and a 300 m² technology centre, a total of 27 EDAG "light designers" develop and inspect not only headlights and rear lights, but also ambient and functional lighting. "Ambient lighting has become an absolute trend in our sector, and will increase in importance in the future, with the advent of autonomous driving," explain Franziska Lange, Martin Fiege and Philip Schatz. The EDAG light designers are called upon to create a number of different lighting moods in line with our customers' requirements – from a chilled, relaxed atmosphere to optimum lighting conditions for the workplace. It goes without saying that both the quality and safety of lights are of paramount importance. The EDAG light specialists make sure, for example, that light lines are homogeneous, and avoid any unwanted hot spots. In our light laboratory, we can carry out any verification necessary, especially for close-range illumination, and examine the results of our own or customers' developments. In this way, EDAG provides extensive services in the fields of luminance images, spectrometer measurements, reflection measurements and transmission measurements, and even light intensity measurements.

This rounds off the range of services provided by EDAG's lighting team, which has been successfully offering the structural development and simulation of exterior and interior lighting and class A surfacing for exterior components since 2010.

"Even after all these years, we are still fascinated by the sheer complexity of lighting technology. Leaving structural aspects aside, light is also a physical phenomenon and subject to the laws of nature, and while we cannot change these, we still constantly come up with new ways of circumventing - or rather making use of - physics," is the unanimous opinion of the EDAG light team.

Enthusiasm for their field of work often also leads to the Wolfsburg-based team creating their own innovative developments – such as the first ever additively manufactured headlight eligible for certification, the "EDAG GenLight". The aim of this innovative project was to further enhance the luminous power of the LEDs used by means of an active/passive cooling system. By applying additive manufacturing methods, the EDAG team successfully produced bionic cooling structures and innovative components that guarantee optimum heat dissipation inside the headlight. The chief attraction, apart from improved efficiency, was that it proved possible to reduce the weight of the headlight and in doing so bring about its virtual photometric eligibility for certification. The "GenLight" project demonstrates how in the future it will be possible to serve important market segments in the low-volume and high-performance sectors at lower cost and with significant savings in investment, as the production method involved is largely tool-less.

The extended light laboratory is a symbol of how much EDAG, as an innovative engineering company, does for mobility, and of the great changes it will continue to bring about in the future.