At the IAA in Frankfurt, the EDAG Group will be presenting not just its live engineering project #collectivio, but also seven technological innovations from the fields of lightweight design and eMobility. As the growing number of variants continues to increase due to the alternative powertrains available, greater flexibility and above all more lightweight soltions, both for components but also in manufacturing, are called for. Wiesbaden-based engneering specialists EDAG have already in recent years provided impressive evidence of the company's engineering skills in additive manufacturing. EDAG are continuing this success story this year with a number of projects including the in-house development of a new, service-oriented E/E architecture.

For us, lightweight design competence, car IT and production solutions remain key futuroriened subjects. I am delighted that we can once again offer a real firework display of proactively de-veloped technology concepts in these future fields here in Frankfurt, declares Jürgen Vogt, CEO of the EDAG Group.

Vehicle electrification is an important component of future mobility for EDAG, and has formed a fixed and integral part of our research and project work for many years now.

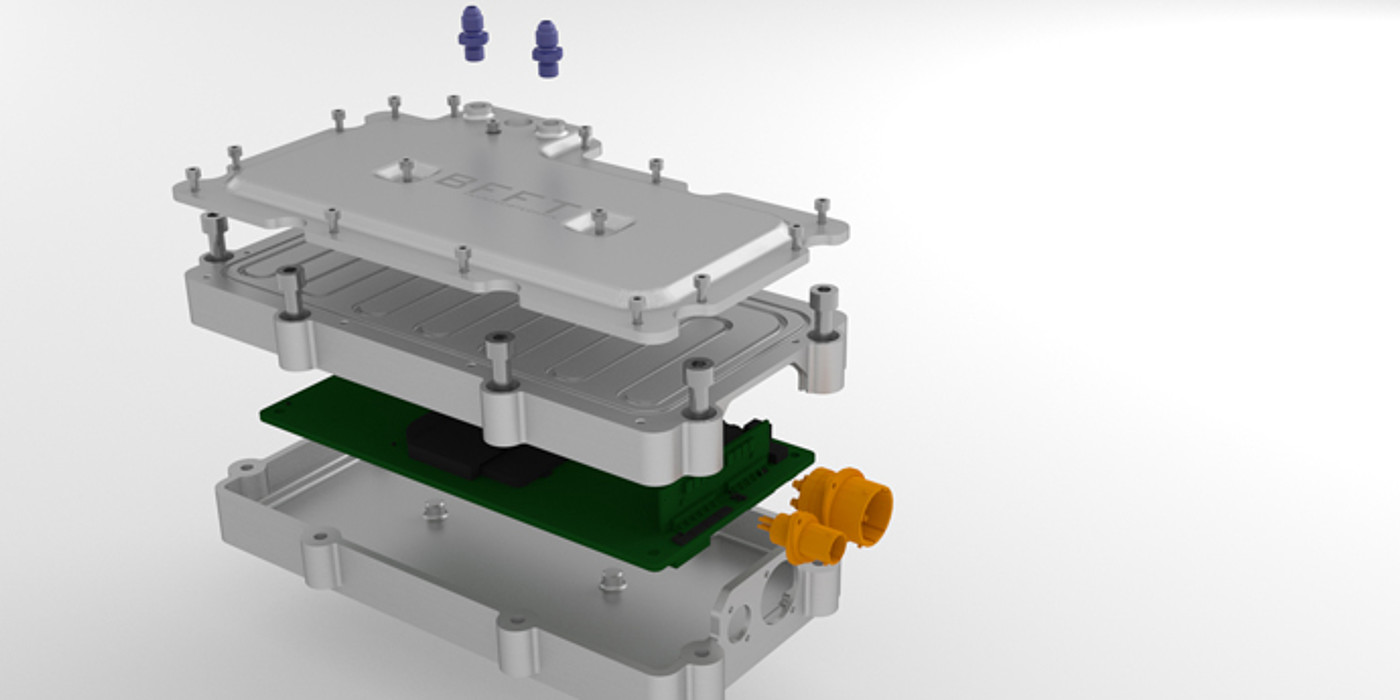

At the start of the IAA 2017, EDAG will be bundling its electrification competencies in the new brand E-Drive Solutions, the head office of which will be opening at the new EDAG|BFFT branch in Berlin at the end of the year. All of EDAG's electrification-related activities are to be concentrated under this brand, to enable us to offer customers fully integrated solutions for future mobility. As an example of our involvement in the eDrive solutions sector, we will be exhibiting our 800-volt DC/DC transformer, which was specially developed for motorsports, at the IAA 2017. Top efficiency and its extremely compact design are key characteristics of the transformer. Modern semiconductor technology based on silicon carbide and gallium nitride also permits high switch speeds and optimum loss reduction. An efficiency factor of up to 98% is achieved in this way. Systematic space optimisation and weight reduction provide particularly valuable support in the fields of motorsports and automotive lightweight design.

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/Group/Unternehmen/Presse/Pressemitteilung/2017/pm_19_09_2017_1.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/Group/Unternehmen/Presse/Pressemitteilung/2017/pm_19_09_2017_2.jpg)